You might have seen a rubber or strip like structure when you disassemble an engine.This rubber like structure is called gasket.We will know the importance of gaskets in engines in this article.

The head gasket in modern vehicles is comprised of several layers of steel material entwined with elastomer, making them more durable and longer lasting. Vehicles produced in the past were equipped with gaskets created by graphite or asbestos. In comparison, today’s gaskets are better as they are less prone to leakage and have little to no health risks as opposed to asbestos produced gaskets.

The main functions of head gasket as as follows:

1.)The gasket joins irregular surfaces (we speak in terms of millimeter microns). For this reason, it is necessary to insert a softer material, such as a fiber or an elastomer between both surfaces which is able to adapt to those imperfections, which ensuring a perfect sealing.

2.)It maintains the sealing need and prevent leakage between the two crucial engine parts, when being subjected to the compression process.

3.)The gasket performs the task of separating the passage of oil and water that pass through the block and cylinder head of the engine.The head gasket keeps the chambers separated to ensure there is no cross-contamination of fluids.

4.)It prevents dust and dirt from getting into the engine and causing damage.

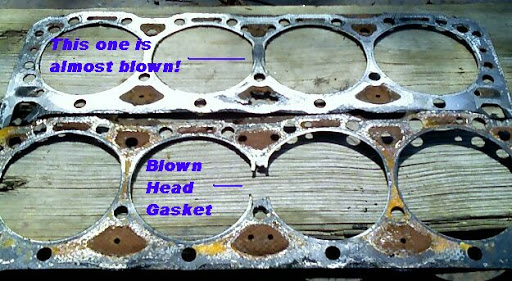

When the head gasket has blown, it’s critical that it be addressed immediately. Continuing to operate a vehicle with a blown gasket can cause serious and irreparable damage to the engine. When gasket is blown, you may notice a few or all of the following symptoms:

>Overheating – Caused by a lack of or reduced coolant. Also caused by hydrocarbons entering the cooling system.

>White, Blue, or Grey smoke – Indicates coolant or oil has entered the combustion chamber.

>Loss of Power – Due to a lack of compression resulting in sputtering, loss of power, and reduced fuel efficiency.

>Discolored Oil – A chocolate milk-looking oil is indicative of coolant mixing with oil in the engine.

So,next time when you face above problems, do not forget to check your gasket once.Thank you for reading this article.

Download this article in PDF Form:

Click "HERE" to Download

Download this article in PDF Form:

Click "HERE" to Download