You might have seen these flag-like objects on airports and wondered what are these used for. This cone-like object plays a vital role in the aviation industry. In this article, we are going to discuss the importance and purpose of this object.

These objects are known as industrial windsocks or “wind

cones” or sometimes “air cones”. It is a kind of kite tube manufactured

from synthetic cloth, nylon or rubber in the shape of an ice cream cone that is

open at one end by a stiff metal ring.

The main purpose of safety aviation windsocks installed on

airfields, international airports, helipads, and heliports is to give the

pilot a quick reference about wind direction and the approximate wind speed. Pilots

need to calculate wind velocity during take-off and landing to ensure it is

safe for the aircraft. The wind direction and speed can directly impact the

distance a plane needs to travel on the ground before taking off or coming to

a stop on the runway. Before accelerating before take-off, pilots take a

quick glance at it and give the necessary input while strolling down the

runway.

Although most airports also provide more accurate weather

information for pilots, from automated weather observation systems but sometimes

the windsock is the only indication of wind speed and direction.

Working of windsock:

Windsocks may be solid orange, yellow, or white and should

not have any lettering or logos. The ones that are the best indicators of wind

speed, however, have alternating colors—such as orange and white—or have

stripes at key points.

The wind direction is the opposite of the direction in which

the windsock is pointing. This means if the wind blowing from the West the

windsock would point towards the East.

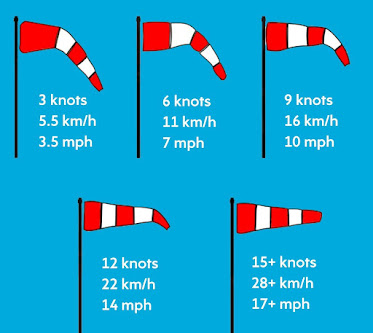

Windsock is made to orient against the wind when the wind

speed reaches three knots (3.5 mph). At that wind speed, only the first segment

of the windsock will extend. The second segment of the sock extends when the

wind speed has reached six knots; the third segment, nine knots; and the fourth

segment, 12 knots. At a wind speed of 15 knots (17 mph) or more, the windsock

will fully extend and point away from the direction from which the wind

originates.

Windsock data is used in every aspect of aviation, not just at airports large and small. In addition to being applied at military airstrips and private airfields, and at commercial or domestic helipads, windsocks are also used in areas where people take paragliding or parachute flights. You may even spot a windsock at a hot air balloon launch and landing site, to assist in safe flying.