We might have come across the ads in tv and other media stating as Volkswagen Bluemotion Technologies. This technology for which Volkswagen has exclusively developed for its automobiles was quite impressive. In German 'Volks' means people and 'Wagen' means car. So together, it's called people's car. Similarly the Bluemotion technology also has its meaning. 'Blue' personifies our blue planet Earth and 'Motion' refers to the movement of automobiles.

This technology is based on the theme of using eco friendly measures and ideas to protect and conserve the environment without compromising the performance of automobiles. Therefore it's an important milestone and also a complete set of new innovations for green tomorrow. Many environmental issues like global warming, climatic changes, Ozone depletion, etc are caused due to increased level of carbon emissions from automobiles.

The Bluemotion technology has been developed by taking all these factors into account and it puts its solution in their automobiles.

This technology entirely focuses on the following areas such as,

- Engine with new technology and revised engine mapping to provide minimal carbon emissions.

- Transmission systems with optimized gear ratios assisted in a perfect way of delivering power seamlessly.

- The auto start-stop system.

- Bi-fuel engines using conventional fossil fuels in combination of LPG (Liquified Petroleum Gas) & CNG (Copmressed Natural Gas).

- Brake energy regeneration.

- Producing Hybrid and electric automobiles.

- Using low rolling resistance tyres.

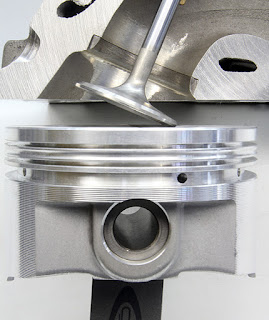

Engine Technology: The newly developed TSI (Turbo and Stratified Injection) & TDI (Turbo Direct Injection) are extremely economical. The fundamental characteristics shared by all TDI engines are high-pressure fuel injection and variable turbine geometry for excellent cylinder charging and an efficient combustion process. At the same time, Volkswagen is increasingly deploying innovative common-rail technology.

Pioneering technology is used in the TSI engines, combining direct petrol injection with a turbocharger or charge compression with both a turbo and a supercharger, enabling them to deliver impressive performance figures and torque and to provide the driver with the full spectrum of driving pleasure despite the smaller engine. The combustion of the petrol is particularly efficient, with the result that the power output of the TSI engines is considerably higher than is the case with conventional, naturally aspirated engines.

Transmission systems: The innovative DSG dual-clutch gearbox from Volkswagen offers previously unattained shifting comfort that lifts what were once well-defined boundaries between automatic and manual transmissions. This is a 6-speed gearbox that combines the sporty character and low fuel consumption of a manual gearbox with the comfort and convenience of an automatic. Another highlight: gear changes are executed without any interruption of the driving power.

The auto-stop system: The Start/Stop system means your car can virtually stop its engine by itself. It works through the clutch, so when you come to a standstill, you just select neutral gear, release the clutch and the engine switches off with a Start/Stop symbol appearing on the dashboard. When you want to move off again you simply dip the clutch, the engine restarts and you can select first gear and pull away. The system can easily be deactivated, if you wish, by a switch within easy reach.

Bi-fuel engines: Bi-Fuel is a so-called hybrid powertrain developed for smaller, popular models (such as the Golf and Golf Plus). This means that you can use a second fuel in addition to the main fuel type: in this case LPG (Liquefied Petroleum Gas). Helping you “drive” down costs while offering unique flexibility at the same time.

Brake energy regeneration: The alternator voltage is increased when slowing down and braking. This increases battery charging and helps the car slow down. The alternator load is then reduced when accelerating to lighten the burden on the engine and cut fuel consumption. It Recovers and uses the energy produced by braking, reducing fuel consumption and emissions.

Hybrid and electric cars: The next concept is to produce new type of hybrid and electric cars. Hybrid cars are fuel economical and eco friendly. The designing of electric cars providing the ease of use of like conventional cars is being carried out.

Low rolling resistance tyres: Low rolling resistance tyres are part of BlueMotion Technologies. They need less engine power to move the car forward, saving fuel and helping to cut emissions, while still offering excellent performance.

Some of the existing models equipped with Bluemotion technology areNew Polo,Passat.Toura,New Beetle.

Hybrid and electric cars: The next concept is to produce new type of hybrid and electric cars. Hybrid cars are fuel economical and eco friendly. The designing of electric cars providing the ease of use of like conventional cars is being carried out.

Low rolling resistance tyres: Low rolling resistance tyres are part of BlueMotion Technologies. They need less engine power to move the car forward, saving fuel and helping to cut emissions, while still offering excellent performance.

Some of the existing models equipped with Bluemotion technology areNew Polo,Passat.Toura,New Beetle.